A lot of big numbers get quoted on off-road recovery gear, but sometimes these might not mean what you think, and too often are just outright useless.

I won't "name and shame" any brands here, but below are some quotes from online listings for various recovery ropes and shackles.

1) "6,000kg strength"

2) "12,000lb breaking limit"

3) "3 tonne rated capacity"

These numbers might seem like more than enough for any 4x4 recovery situation, but if we break them down the usefulness of this information starts to fall apart pretty quickly.

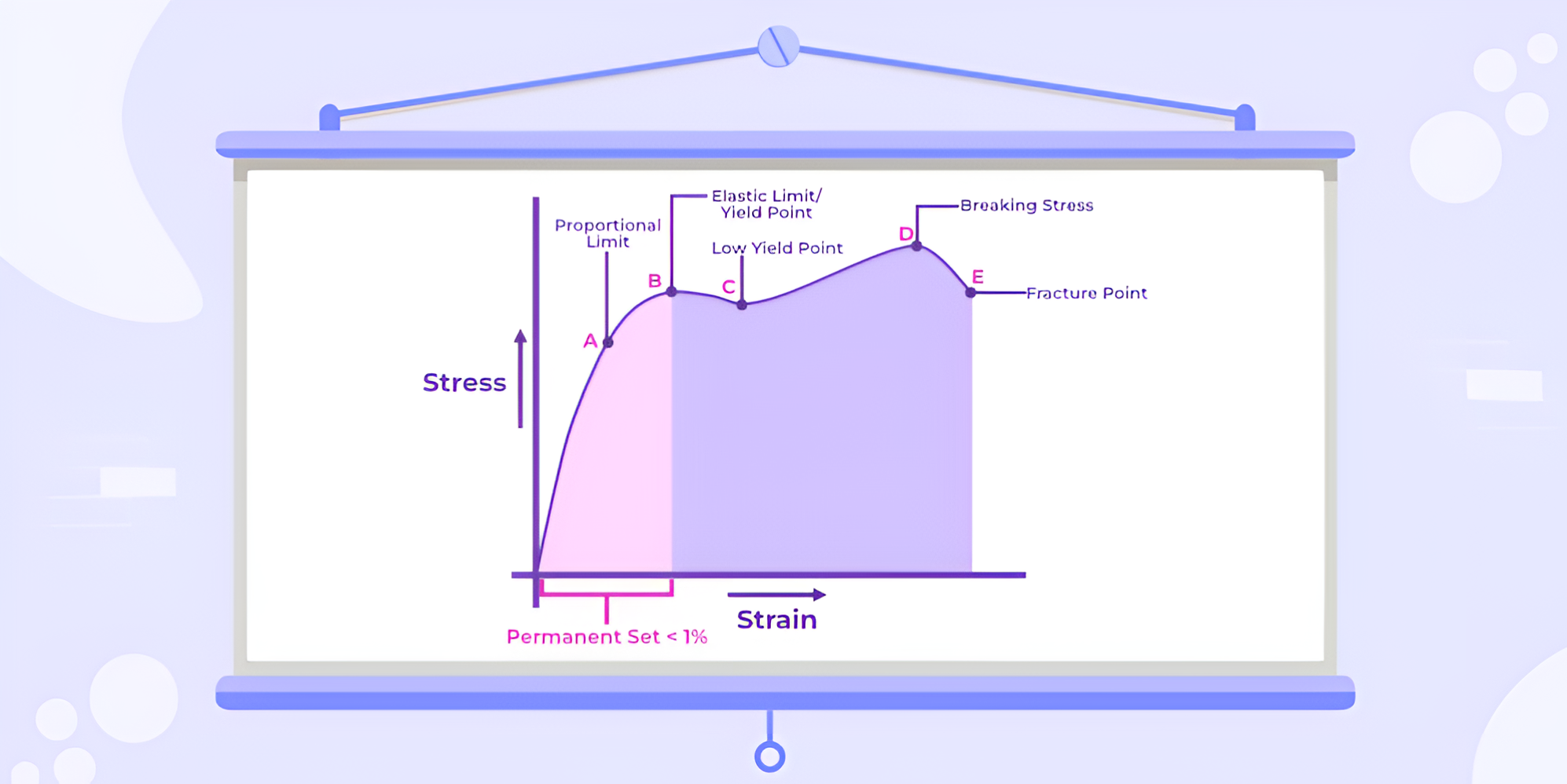

Before we get to that, let's define a few key terms as they relate to high-stress applications like 4x4 recoveries. Remember as we move forward too that all materials, even things that seem as unyielding as steel, have some elastic properties. This is key as we get into high-stress applications.

Image credit: GeeksforGeeks

The key points to keep in mind from the chart above are:

Proportional Stress Limit - Within this range, the equipment will experience no deformation, or so little deformation that it will return to its original shape.

Elastic Limit/Yield Point - Beyond this point, the rate of deformation increases, and the equipment will not return to its original shape, and is now damaged.

Breaking Stress/Strength - This is the point that equipment breaks, fractions, or tears, and the equipment is effectively destroyed.

With that out of the way, we'll break down the recovery gear claims listed above. Going in order:

1) "6,000kg strength" - In this listing "strength" means... what exactly? Breaking point? Some "safe" amount of load? Safe as defined by who? By what criteria has it been deemed safe?

2) "12,000lb breaking limit" - This may seem ample, but this tells us nothing about how much stress the equipment can take in actual real-world use. Its Elastic Limit could be 9,000lb, 6,000lb, or less, we have no idea. Loading this piece of equipment with several thousand pounds less than its "breaking limit" may still mean it's deformed to the point it's unusable.

3) "3 tonne rated capacity" - This might seem like the least vague of the 3 statements, but again, if approaching these limits it doesn't provide enough information to know if loading it with 3 tonne is even remotely appropriate. Does "rated" mean breaking the limit? If it is meant to imply a reasonable working load, what is the margin of safety? Is this for a single-time application, or can it repeatedly be subject to this much force without any ill effects?

In any of the situations above, was this based on a single test, or repeat testing? If repeat testing, was this the lowest result, or an average? If it's an average, how do you know if the strap or shackle you've purchased is on the high or low end of that average? Was the testing conducted on a single batch of manufactured products, or conducted across multiple batches to factor in manufacturing variances?

The answer to all of these listings is you just can't tell.

Unfortunately, there are no universal testing standards, and while there is some accepted terminology that has been brought over from the rigging/lifting industry, there is often no consistency in what information is provided on 4x4 products. Many professional industries and companies do develop appropriate standards of their own, but when it comes to grabbing something off your local 4WD shop shelf, this information often isn't there.

How to properly determine the rating of recovery equipment

As we've discussed, just knowing a "rating" or "breaking point" alone doesn't really tell us anything useful. There are multiple factors to take into consideration together to properly determine if the recovery equipment is appropriate for your needs. The terms you should know are:

Minimum Breaking Stress / Strength (MBS) - As already covered, this is when the equipment will completely fail.

Working Load Limit (WLL) - WLL is the maximum amount of load that should be placed on the equipment, as determined by the manufacturer. Note that "WLL" is a specific term; this is not synonymous with terms like "tested" or "rated".

The WLL should be included in the specifications/labels for any quality soft recovery products, and cast into the metal of steel shackles etc.

Safety factor - As covered above, knowing only the breaking strength or WLL doesn't tell the whole story, the safety factor is what completes the picture.

Safety Factor is the ratio of WLL to Breaking Stress. For example:

a) A shackle with a 3 tonne WLL and safety factor of 2:1 has a Min. Breaking Stress of 6 tonnes.

b) A shackle with a 3 tonne WLL and safety factor of 5:1 has a Min. Breaking Stress of 15 tonnes.

c) A shackle with a 3 tonne WLL and safety factor of 10:1 has a Min. Breaking Stress of 30 tonnes.

All of the above are "3 tonne" shackles according to their manufacturers but with dramatically different standards and limits. Some real-world examples of these could be a soft shackle (a), a snatch block (b), and a steel bow shackle (c). Each could have a WLL of 3 tonne, but their respective Breaking Stress could be worlds apart.

You can start to picture now how just knowing the WLL or MBS limit of your equipment doesn't tell you where the weakest link in your recovery is.

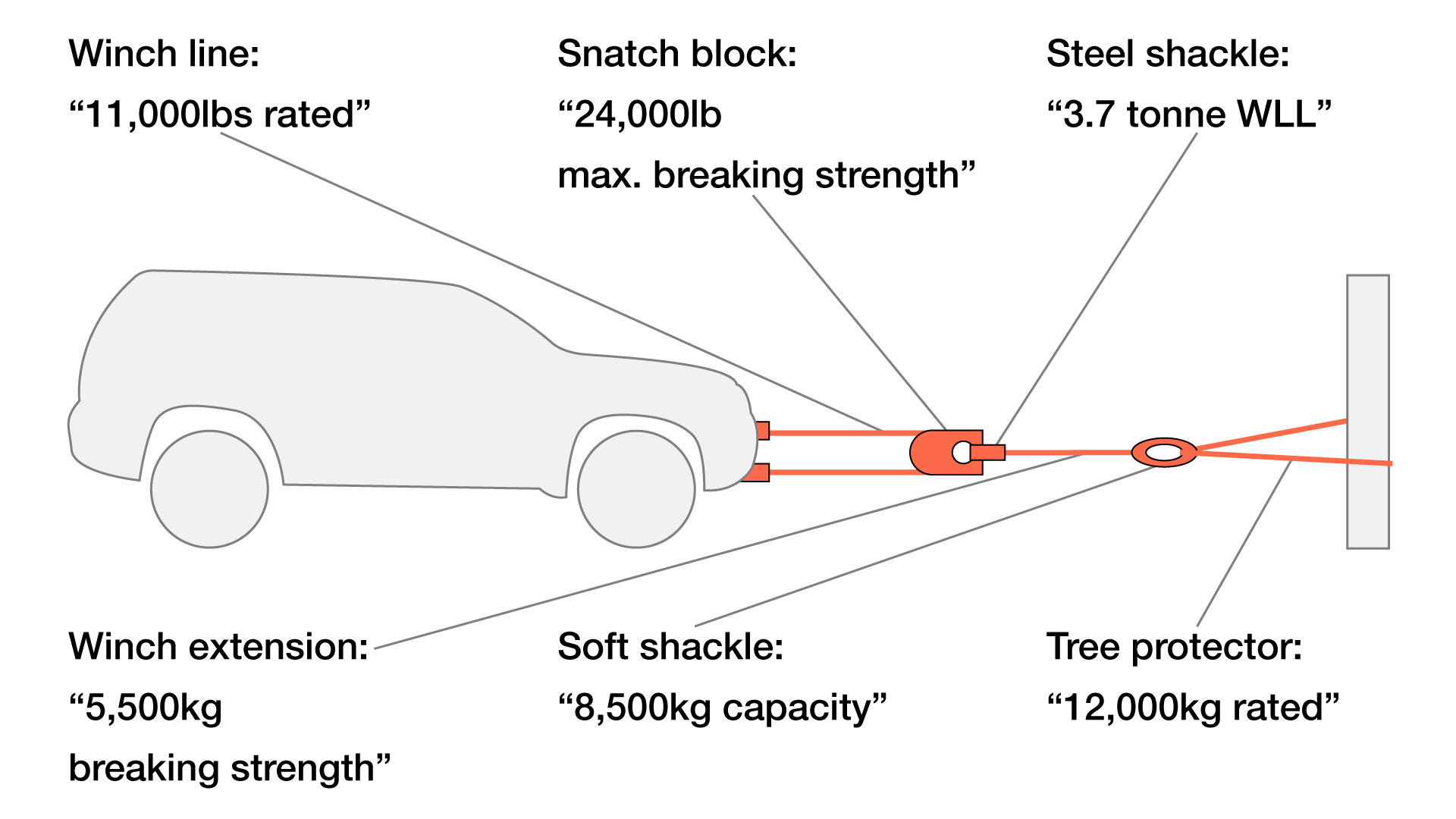

On a fairly standard winch recovery, you could have chained together (as in the picture below) a winch line configured for a double line pull, snatch block, steel shackle, a winch extension strap, a soft shackle, and a tree protector as part of a single recovery.

- Winch line: "11,000lbs rated"

- Snatch block: "24,000lb max. break strength"

- Steel shackle: "3.7 tonne WLL"

- Winch extension: "5,500kg breaking strength"

- Soft shackle: "8,500kg capacity"

- Tree protector: "12,000kg rated"

Above are figures provided from real products all sold in the same market. As you can see, they're all over the place, with zero consistency. Without knowing the WLL and safety factor for all the equipment, you have no idea what an appropriate maximum load really is.

The snatch block might "break" at 24,000lbs, but be deformed to the point of being useless at half that.

The steel shackle would be the strongest piece of equipment if it has a 5:1 safety factory, or could be the weakest if its manufacturer works on a safety factor of 1:1.

The soft shackle could break before the tree protector, or after, even though the soft shackle's "capacity" is 2/3 of the tree protector's "rating", because comparing these terms is meaningless without more information.

Buying tips, and things to avoid

Dos

- Ideally, the equipment should state both the Working Load Limit and Min. Breaking Stress. From this, you can work out the Safety Factor and be well informed on the equipment's capabilities.

- If only the Working-Load-Limit is specified, since you can't know the safety factor and breaking limit from this, I would suggest reducing the WLL by 20% and using that as your new maximum load for that piece of equipment.

- If only the Min. Breaking Stress is specified, I'd suggest loading it with at most 50% of that figure as a realistic maximum.

The reason for reducing the load in the last 2 cases is that without the rest of the information you don't know how rigorous the testing standards were or what the manufacturer has defined as an appropriate working load for repeat use.

Factor 55 does a solid job of providing informative labels on their soft shackles (pictured below). Ideally, we'll see more of this on equipment from other manufacturers, too.

If opting for soft shackles, also don't forget to regularly inspect and clean them after use. While a soft shackle may initially have a WLL of several tonnes, they are ultimately a soft material and are subject to abrasion and wear every time they're used. A steel bow shackle should last many years without any ill-effect when used properly, soft shackles will gradually be getting weaker with repeat use, especially when used against steel equipment or in dirty conditions.

Don'ts

"Average Tensile Strength" - ATS is another figure sometimes quoted on equipment. By definition of an average, a portion of the equipment must be below this figure. If your shackle has an ATS of 4 tonne, did you luck out and get one capable of taking 5 tonne of load, or did you get one from the bottom of the barrel that will fail under 3 tonne? You won't know until it happens.

"Safe working load" - SWL is an old term that has since been replaced by WLL. While these effectively mean the same thing, the term SWL has stopped being used in the US, Australia, and Europe for over 20 years, as saying any setup is unconditionally "safe" as long as it's under the maximum load is not correct.

As with WLL though, if this is the only number provided, you still don't know the Safety Factor or Breaking Stress.

Unrated equipment - If equipment has no information on it at all, just don't buy it. Period. Reputable brands take safety seriously, and no company that has gone through the effort of rigorous safety testing will leave the information out of their products.

There are plenty of quality alternatives out there. By using blank gear you're gambling on the safety of your vehicle, and yourself.