Image credit: Outland Outfitters

As you start off-roading further afield, and into more complex terrain, tire pressure becomes a critical component of your off-road capability and safety. Loose services, rock-crawling, mud, or sand driving all require dramatically different pressures for optimal performance, compared to tire pressure for the road.

( See our article Tire pressures for mud, sand, rock-crawling, and corrugated roads for more on off-roading tire pressures. )

While you can air down your tires by simply pressing a key or fingernail into your tire stem’s valve to release some air, this process is painfully slow when dropping to low pressures. Here’s why…

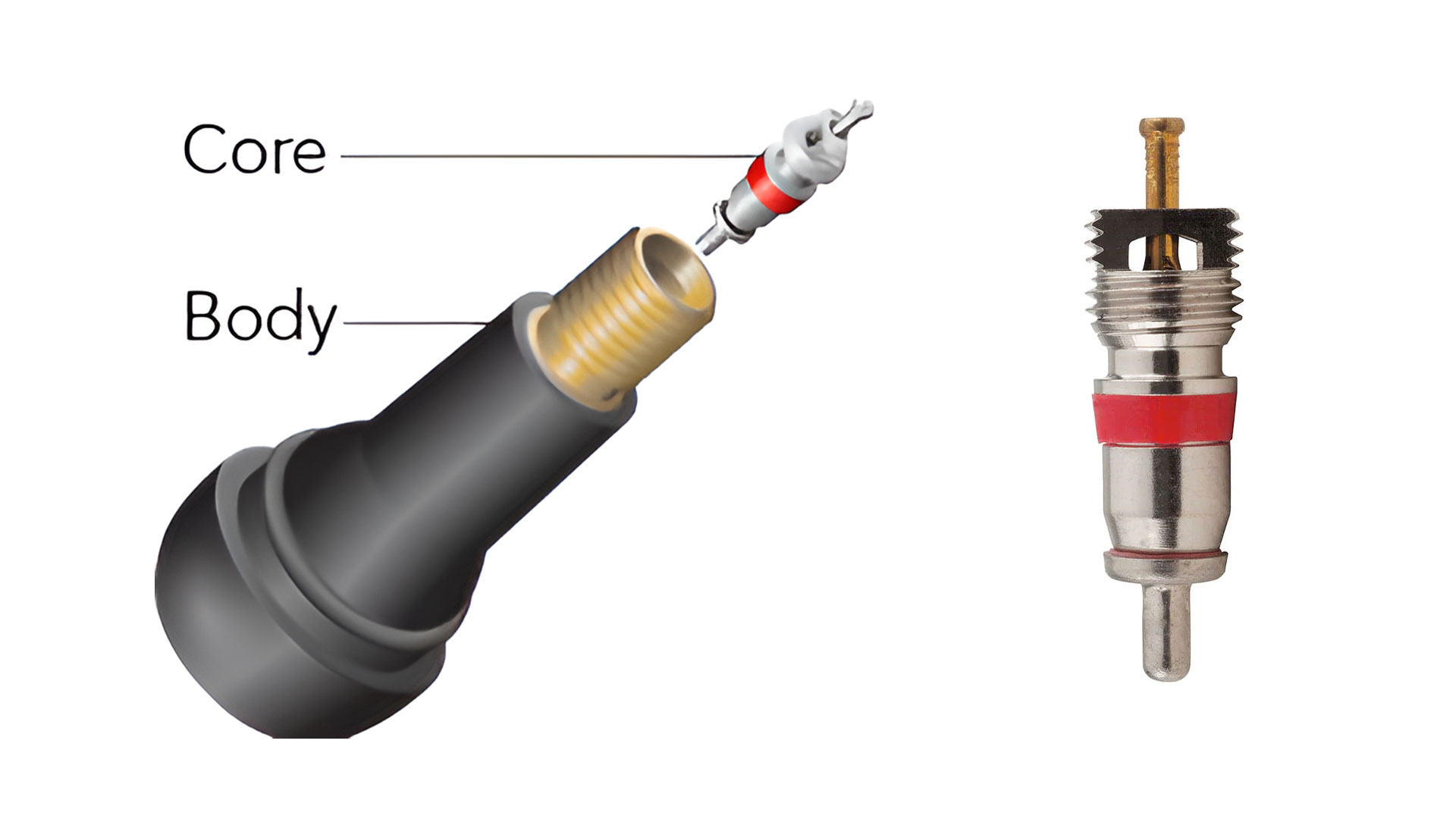

Your tire stem is made of two parts: The stem body, which is basically just a tube, and the valve core which opens to allow airflow, and closes when your tire is at the desired pressure to keep air in.

The problem is, that the valve core itself occupies most of the stem tube, only allowing a fraction of the potential air to flow out when open.

This is where tire deflators come in.

Rather than just opening your valve core to allow air to escape, a tire deflator completely removes the valve core, removing the obstruction it creates and increasing airflow 10-fold.

The first time you use a tire deflator, the magnitude of this difference will be immediately apparent to you. Pushing the valve core with a key lets out a hiss of air, removing the core turns this into a roar. You can literally see the tire deflate before your eyes.

How to use a tire deflator

Tire deflators are fairly simple to use. Units like the ARB E-Z Tyre Deflator combine a sliding valve attachment that screws onto your valve stem thread, a plunger-type rod that grasps the valve core, and a pressure gauge. After screwing the deflator to your tire stem, the plunger is pushed onto the valve stem and used to unscrew and remove it, holding it inside the deflator. The deflator’s sliding valve can then be opened to allow air to rush out.

Closing the slider then seals the stem once more, and the current tire pressure will be shown on the gauge. This process is repeated a few times until you reach your desired pressure, the plunger is then pushed back down to screw the valve core back in. You can see the process in the video below from Yota Xpedition.

This might sound a bit abstract without doing it yourself, but once the inflator is in your hands, knowing you’re connected to the right parts becomes fairly intuitive by feel.

One important note: When reinserting the valve core, you want to be sure this is locked in. The last thing you want is to remove the deflator only to have the core fly out and get lost, and your tire completely depressurizes with no way to re-inflate in. But again, this will become easy to do by feel with a little practice.

Deflator options: Single deflators vs multi-line deflator/inflator

Single tire deflators (pictured at the stage of this article) from different brands will work much the same, the one variant being a multi-line inflator/deflator, which you can see in the image above. These units will have 2 or 4 lines that can be connected to multiple tires at once, allowing you to deflate all tires at once, or attach your portable air compressor to inflate all tires simultaneously.

Maybe this is something you’ll find appealing, but personally, I don’t find there is much practical benefit to them, for the following reasons:

- When deflating, these units do not remove the valve core, rather they just open it, limiting air-flow as already explained above. Yes, your tires are deflating simultaneously, but they’re doing it at a fraction of the speed of a single tire with the valve core removed.

- When inflating tires, it may seem convenient to have all 4 inflating at once. In this case, though, you still have to go around and attach/detach the lines to each tire, the same as you would do one by one with a single inflator. In terms of air-compressor run time, inflating all 4 at once will take 4 times as long as doing them individually; I’m not convinced there is a practical, significant gain to this process. But, to each their own.

- In plenty of circumstances, you may not want all 4 tires to be the same pressure. Wagons or single/dual cab utes with a heavy payload in the rear will need higher pressures in the rear tires than the front in most circumstances, which makes 4-line inflators/deflators unsuitable. Doing the front and rear tires separately with a dual line unit would solve this, but there are still points 1 and 2.

If a multi-line inflator appeals to you, they will get the job done, but they’re not necessary, in this wheelers opinion.

Do you need a tire deflator?

This will depend on how ‘off’ you’re going in your off-roading. Again, for a detailed look into tire pressures for different off-roading environments, see our full article here: Tire pressures for mud, sand, rock-crawling, and corrugated roads

In summary though, if the extent of your off-roading is limited to loose, but firm, surfaces, gravel roads, etc., you can probably get by happily without one. These might dictate you only reduce your tire pressure by 5-10 PSI for a little enhanced traction; a small enough amount that opening the valve by just pushing a key into the stem is quick enough.

Rock crawling, mud, and beach driving will dictate much lower tire pressures, sometimes as much as 20-30 PSI below your road pressures. If you’re doing this with any regularity at all, a tire deflator is going to be a huge time saver and comes highly recommended.

Happy off-roading.

# Tire deflator for 4×4, deflating tires for off-roading, high-speed tire deflating.